Heat-pump dryers save energy by recycling heat within a closed-loop system, reducing overall power consumption compared to traditional ventless models. They use a refrigerant cycle to absorb moisture and reuse the warm air, which minimizes heat waste and moisture loss. This efficient process can cut energy use by up to 70%, saving you money on electricity bills. To discover how these systems work and why they’re so eco-friendly, keep exploring.

Key Takeaways

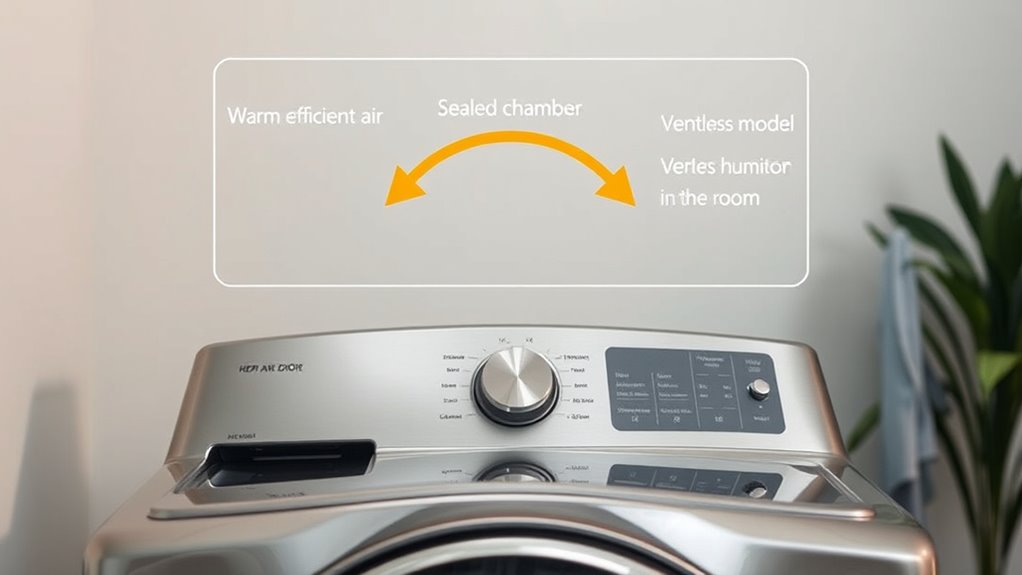

- Heat-pump dryers recycle heat within a closed-loop system, reducing energy waste compared to ventless models.

- They use internal condensation to capture moisture, minimizing heat loss and improving overall efficiency.

- Higher energy factors in heat-pump dryers mean less electricity is needed for the same drying performance.

- Their advanced refrigerant cycle optimizes heat transfer, lowering power consumption compared to traditional ventless dryers.

- Long-term energy savings offset higher initial costs, with significantly lower annual electricity use than ventless alternatives.

The Technology Behind Heat Pump Dryers and Their Efficiency

Heat pump dryers use a closed-loop refrigeration cycle to dry clothes efficiently by recycling thermal energy. Inside, refrigerants absorb heat in the evaporator coil, then transfer it via heat transfer to generate hot air that dries your clothes. As the moist air passes over the evaporator, moisture condenses on the cold coil, removing water from the system. The refrigerant then releases heat in the condenser, warming the air for continued drying. This cycle relies on refrigerants with low global warming potential to maximize environmental benefits. The closed-loop system minimizes energy loss, making the process highly efficient. With a higher energy factor, heat pump dryers use less electricity, thanks to effective heat transfer and moisture condensation, ensuring your clothes dry quickly while conserving energy. Additionally, advances in Honda Tuning have demonstrated how optimizing system components can further improve energy efficiency in various mechanical applications. Energy-efficient operation is a key advantage of heat pump dryers, as ongoing innovations continue to enhance their performance and sustainability. Incorporating advanced cycle control can further optimize energy use and drying times in these systems. Furthermore, the integration of smart technology in modern heat pump dryers allows for better energy management and user control, further boosting their efficiency. As industry standards evolve, the adoption of eco-friendly refrigerants is expected to improve the environmental profile of these appliances.

Comparing Energy Consumption: Heat Pump vs. Traditional Ventless Dryers

Compared to traditional ventless dryers, heat pump models consume markedly less electricity, making them a more energy-efficient choice for your laundry routine. They use around 130-150 kWh annually, compared to 600-650 kWh for standard ventless dryers, delivering substantial savings. Their closed loop refrigerant cycle recycles heat, reducing energy waste and moisture loss. Additionally, they often incorporate changing gears technology to optimize drying performance and minimize energy use. The table below highlights the key differences:

| Feature | Heat Pump Models | Ventless Dryers |

|---|---|---|

| Energy Consumption | 130-150 kWh annually | 600-650 kWh annually |

| Drying Time | Slightly longer | Shorter |

| Moisture Removal | Internal condensation | Exhaust venting |

| Efficiency | High | Moderate |

Furthermore, heat pump dryers are designed with energy conservation principles, ensuring minimal environmental impact during operation. In addition, their refrigerant cycle enhances overall efficiency, making them a sustainable choice.

Practical Benefits of Recirculating Warm Air and Internal Condensation

By recirculating warm, moist air internally, heat-pump dryers substantially reduce energy waste and eliminate the need for external venting. This process relies on internal condensation, where moisture is captured on cold coils, allowing the dryer to reuse heat through heat recycling. The closed-loop system maintains a steady internal temperature, preventing heat loss and enabling continuous moisture removal without expelling warm air outside. This internal heat exchange maximizes energy efficiency, as the dryer consumes less power to sustain drying cycles. By recycling heat within the system, heat-pump technology markedly lowers reduced energy consumption compared to traditional models. The moisture capture process ensures effective drying while conserving energy, making these dryers a practical choice for efficient, eco-friendly laundry care. Internal condensation is a key feature that enhances the overall energy savings of heat-pump dryers.

Cost Savings Over Time and Environmental Advantages

Although the initial cost of a heat pump dryer is higher, their energy efficiency results in significant cost savings over time. You’ll notice lower energy consumption—using 4-5 times less electricity than ventless models—which translates into annual savings of over $140. The payback period typically ranges from 3 to 8 years, making long-term savings worthwhile. Plus, eco-friendly refrigerants with low GWP reduce greenhouse gas emissions, offering environmental benefits and supporting sustainable laundry practices. Incorporating energy-efficient technology further enhances these advantages by optimizing performance and reducing operational costs. Additionally, the environmental impact of heat pump dryers is minimized due to their lower emissions and reduced energy use. Implementing sustainable appliances can also contribute to broader efforts to reduce carbon footprints. Using advanced heat pump systems is another way to maximize these environmental benefits and efficiency gains, aligning with a growing focus on eco-friendly solutions in modern home appliances.

Factors Influencing Energy Savings and Overall Performance

Several factors influence how much energy a heat pump dryer can save you in the long run. Energy efficiency depends on the moisture removal process, which relies on a well-fine-tuned refrigerant cycle. Higher Combined Energy Factors (CEF) indicate better appliance efficiency and lower annual energy consumption. The choice of low-GWP refrigerant, like R-290, enhances environmental impact by reducing greenhouse gases. Drying time, typically 50-80 minutes, affects overall energy savings, as longer cycles use more power. Cycle performance plays a key role; models with superior cycle performance maintain ideal efficiency even during extended drying. Additionally, incorporating vegetable juices into your diet can support your overall health and detoxification efforts, complementing eco-friendly household choices. Proper maintenance and cleaning of the dryer components can also sustain peak efficiency over time. Moreover, the refrigerant cycle efficiency is crucial in achieving optimal energy savings, as it directly impacts the drying process. Implementing smart controls that optimize drying cycles can further enhance efficiency and reduce energy consumption. Being aware of industry standards helps ensure you select appliances that meet energy and environmental benchmarks. Ultimately, these factors determine the overall energy savings and environmental benefits, making a well-designed heat pump dryer a smart, eco-friendly choice for your laundry needs.

Frequently Asked Questions

Do Heat Pump Dryers Really Save Money?

Yes, heat pump dryers really save you money. They use 4-5 times less electricity than traditional dryers, which means lower energy bills over time. Although they cost more upfront, you’ll see savings within a few years due to reduced utility costs. Plus, their eco-friendly design helps the environment. So, if you want to cut costs and be more sustainable, investing in a heat pump dryer is a smart choice.

What Are the Downsides of a Heat Pump Dryer?

Like a double-edged sword, heat pump dryers have downsides you should consider. Their longer drying cycles, around 50-80 minutes, can be inconvenient if you’re in a hurry. The small drum limits load size, making them less ideal for large families. Plus, they need regular maintenance, like cleaning coils, which can be tricky. The higher initial cost and potential noise from compressors may also impact your experience.

Are Ventless Dryers More Energy Efficient?

You’re wondering if ventless dryers are more energy efficient. They are, especially heat pump models, because they recycle heat within a closed system, using 4-5 times less electricity than traditional dryers. This reduces energy waste, saves you money on bills, and minimizes heat loss. Ventless dryers condense moisture internally, avoiding ducting and outdoor ventilation, which further boosts their efficiency by recapturing thermal energy for reuse.

Do Heat Pump Dryers Use Less Electricity?

Did you know heat pump dryers use about 4 to 5 times less electricity than traditional dryers? Yes, they do use less power because they recycle heat through a refrigeration cycle, which is more efficient. While drying times might be longer, your energy bill drops markedly. With annual energy consumption around 133 kWh, a heat pump dryer dramatically outperforms standard models, helping you save money and reduce your environmental impact.

Conclusion

By choosing a heat pump dryer, you’re revealing a key that opens the door to energy savings and environmental impact. Like a steady heartbeat, its recirculating system keeps your home and planet healthier. Over time, this quiet guardian of efficiency not only cuts costs but also champions sustainability. Embrace this technology, and let it be the steady pulse guiding you toward a greener, more economical future—where every load turns into a step toward change.